Innovation Known Worldwide

The Mikuni Group manufactures superior products for a wide range of industries, including automotive, commercial vehicles, powersports, general purpose, household and safety, as well as export and sales of aerospace parts.

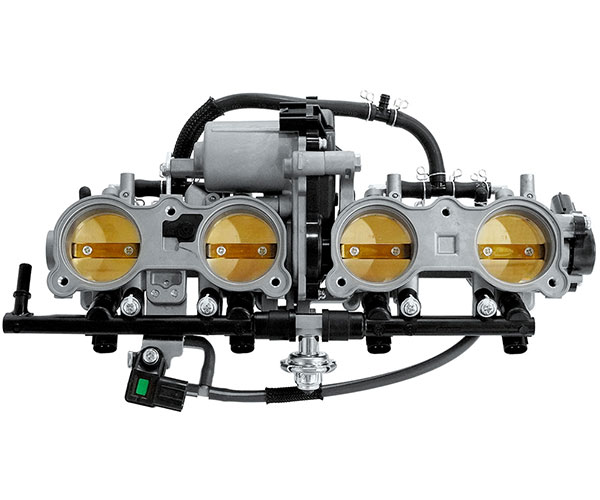

OEM PARTS FOR MOTORCYCLE,

UTV, ATV, SNOWMOBILE, PWC, OUTBOARD ENGINE

Powersports

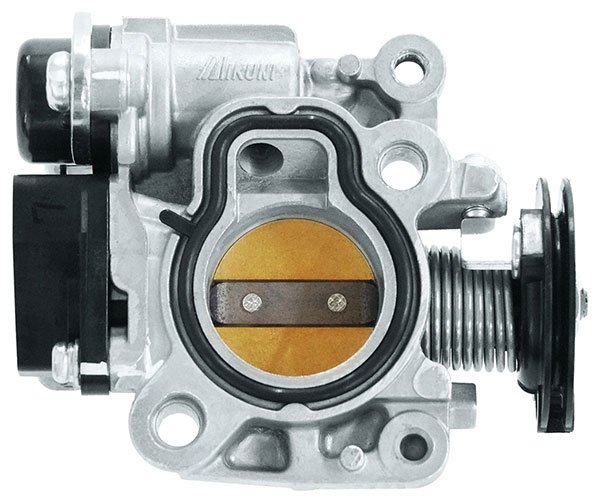

OEM PARTS FOR PASSENGER

& CARGO VEHICLES

Automotive

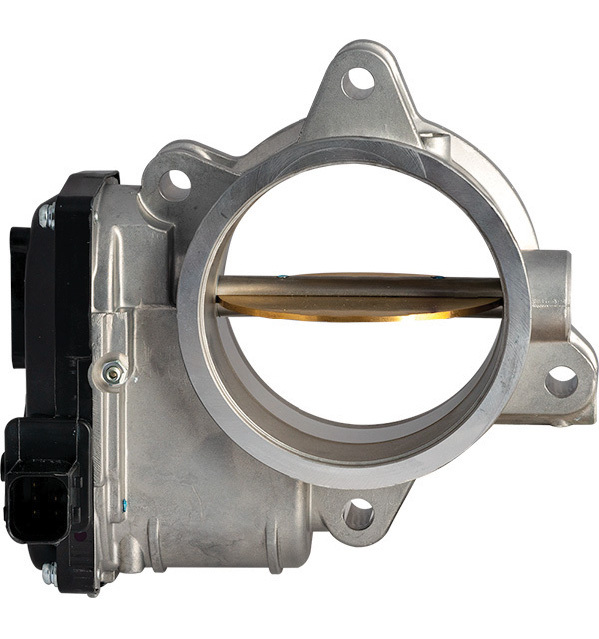

OEM PARTS FOR

COMMERCIAL VEHICLES

Commercial

PERFORMANCE CARBURETORS,

PARTS & ACCESSORIES

Aftermarket

SAFETY DEVICES FOR GAS APPLICANCES

AND WATER CONTROL VALVES

Gas & Water Control

OEM PARTS FOR

GENERAL PURPOSE ENGINES

General Purpose

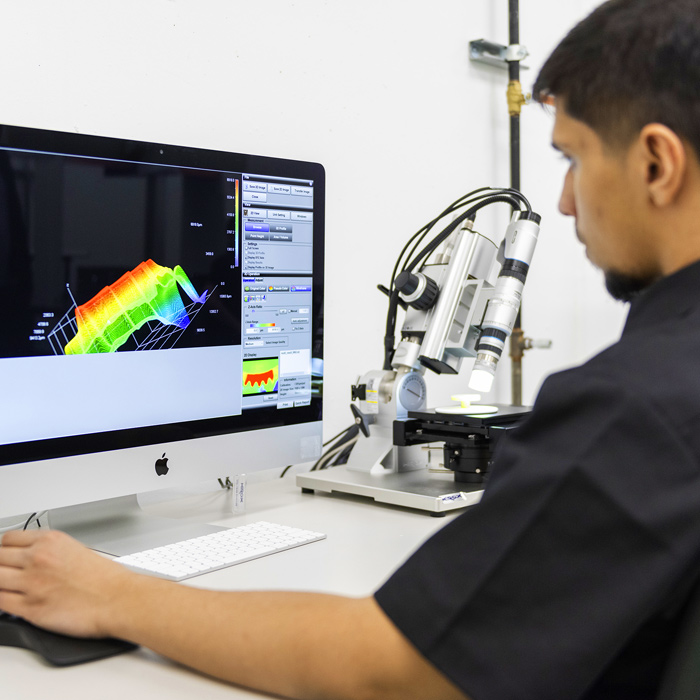

Environmental Principle

We are devoted to our efforts towards a sustainable society, the peaceful coexistence of humanity with the environment and the prosperity of future generations.